Seltzer Tower Soda Fountain System w/ NEW Compact Remote Chiller (REMANUFACTURED)

What You Need to Supply:

- Water supply

- CO2 (carbon dioxide) gas

- Electricity

(We can help you locate syrup & CO2 for your area)

Features:

- NEW Stainless Tower with One (1) Remanufactured Dispensing Valve

Dimensions: 6" W x 9" D x 16" H - Completely Pre-Assembled Ready To Install

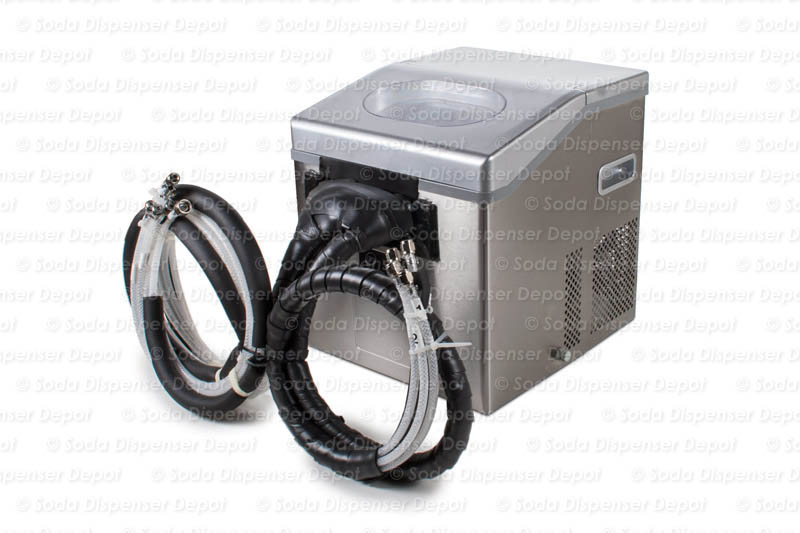

- NEW Compact Remote Chiller

Dimensions: 16" D x 15" W x 17" H - Carbonator

- Primary CO2 Regulator

- A Novice Can Install This—It's ALL Labeled

- See Shipping Rates in Shopping Cart

Complete, remanufactured, seltzer tower soda fountain system with new compact remote chiller. This complete system is designed for home or office use. The stainless dispenser is compact in size and blends in a variety of settings without eating up valuable counter space.

Set up to dispense soda water (seltzer) only.

Very simple hook-up. The lines have been pre-assembled & labeled. ALL of the fittings have been professionally clamped for easy installation.

Also included: Primary CO2 regulator, high pressure hosing, carbonator, and new compact remote chiller.

A brix kit is used to achieve exact syrup-to-seltzer (carbonated) or syrup-to-plain water (non-carbonated) ratios. A brix kit includes a syrup separator and a ratio cup. The process of brixing a soda valve takes only a few minutes per valve and will give you a standard flavor result.

⇒ Add a brix kit to your system order today!

⇛ If you purchase a complete system and a brix kit: We will supply the appropriate syrup separator for your valve type or soda gun. Not applicable to seltzer-only systems.

With your purchase of this system, you will receive an Installation Guide in the form of a Digital Download PDF that includes a link to the Start-up Procedures video for your system. You will receive our PDF document on how to purchase your Bag-in-Box syrup and how to locate CO2 gas suppliers. We also offer FREE technical support to our customers via telephone and email.

This is a remanufactured system. All of the tubing is new. The support equipment is remanufactured (unless otherwise specified). We pressure test, performance test, and bring each component back to manufacturer's specs. The components were previously used so they may have minor dings and scratches due to normal use.